Listeria on conveyor belts is a notorious problem in the meat industry

PROBLEM:

SOLUTION:

FHS Scandinavia and our supplier www.sterilAir.com have more than 80 years of experience in solving such problems. Eliminating listeria on conveyor belts has become part of our standard range as a “plug and play” solution. We have over 1000 of these solutions in Europe, which daily solve microbiological challenges for food producers.

In collaboration with SterilAir, we install UVC equipment that, according to calculations with a specially developed software program from the University of Zurich, is customised for the company’s conveyor belts and other individual circumstances. SterilAir has developed a unique system for precisely listeria challenges on conveyor belts for the meat industry, and that system (T2018) will be installed at the meat producer in question.

RESULT:

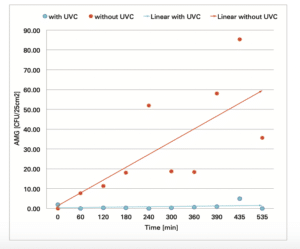

The customer is delighted with both the result and the handling of the equipment and has subsequently invested in equipment for all its production lines.The graph below shows before and after results of testing T2018 conducted at a meat producer in Switzerland by an independent analysis company (see more about the test here)

DO YOU HAVE A CHALLENGE?

Do you need help with your challenge? Fill out the form and we will contact you as soon as possible

FHS SCANDINAVIA