SURFACES

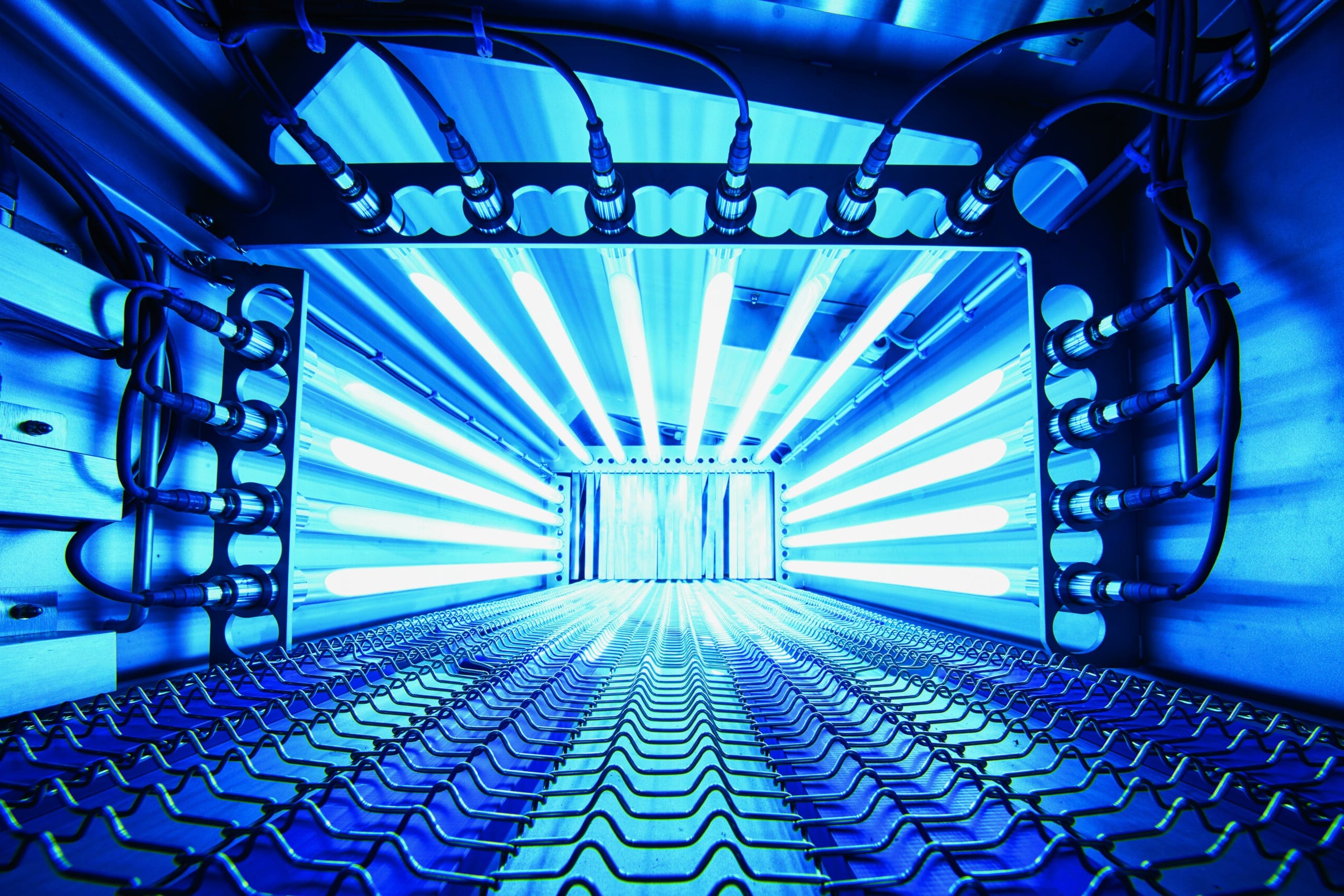

Surfaces that come into contact with the product are more critical than surfaces with no product contact. The surfaces can be, e.g. conveyor belts, filling and draining systems, slicers and containers. By installing a decontamination solution from FHS, you can keep a low germ level throughout the production process and often achieve the same germ level at production stop as at production start.

In general, surface decontamination can also be achieved by using LED working lights 24-7, i.e. around the clock. By switching fluorescent lamps to patented LED lights, you can achieve reductions of up to 1 Log in the room in general, which has proven to be an effective way to control, e.g. listeria.

Before we can suggest a “Food Hygiene Solution”, we need to know about your specific microbiological challenge and your objectives, and then we can find the right solution for you, be it based on UV-C, ionisation, ozone, LED working lights and/or a combination of these dry decontamination technologies.

GALLERY

DO YOU HAVE A CHALLENGE?

Do you need help with your challenge? Fill out the form and we will contact you as soon as possible.

FHS SCANDINAVIA – Denmark